Precision Production and Quality Control System for Cosmetic Packaging

The quality of cosmetic packaging directly impacts product safety and brand image. Professional manufacturing enterprises ensure that every product meets industry standards and customer requirements through precision manufacturing processes and full-process quality control.

Material selection and pre-treatment form the foundation of quality control. For inner packaging materials that come into contact with cosmetic contents (such as bottle bodies and pump heads), strict adherence is maintained to food contact material standards like FDA and EU 10/2011. Food-grade raw materials including PET, PP, and acrylic are selected, with each batch undergoing heavy metal and plasticizer migration tests to ensure safety and non-toxicity. Borosilicate glass is used for glass materials, and annealing treatment is applied to eliminate internal stress, increasing impact resistance by 20% and preventing breakage during transportation. In the pre-treatment stage, plastic preforms undergo aseptic cleaning (achieving a cleanliness level of Class 100), while glass products undergo high-temperature disinfection to provide clean containers for subsequent filling.

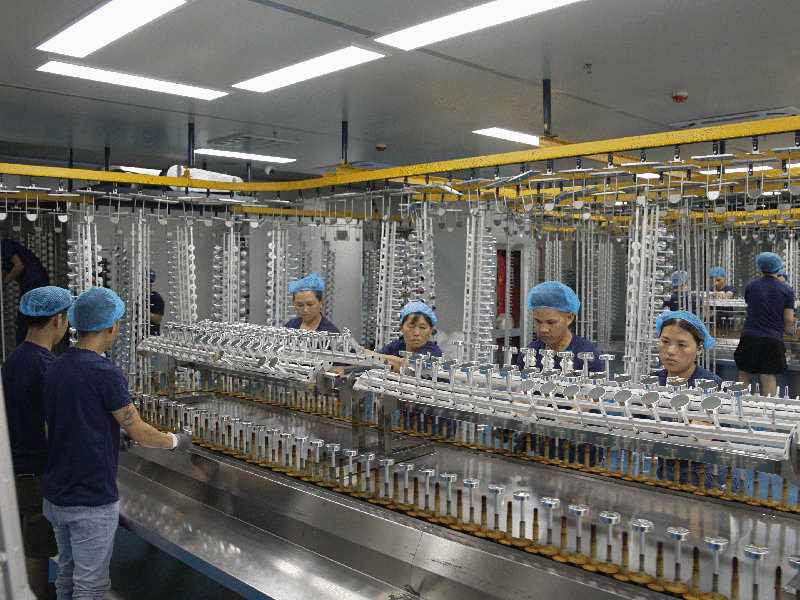

Precision manufacturing processes ensure product consistency. The injection molding process utilizes fully electric injection molding machines with a temperature control accuracy of ±0.5℃, ensuring uniform wall thickness of bottle bodies (with an error ≤0.1mm). The blow molding process optimizes mold design through 3D simulation, increasing the glossiness of bottle bodies by 30% and eliminating defects such as bubbles and scratches. Surface treatment processes achieve precise control: the thickness of vacuum-plated layers is controlled between 5-10μm to ensure uniform metallic texture; digital management is applied to parameters such as light intensity and time in the UV curing process to ensure coating adhesion meets standards (cross-cut test ≥4B). Automated assembly lines employ machine vision inspection to conduct 100% testing on the sealing performance of bottle caps and the smoothness of pump pressing, removing non-conforming products.

The full-process quality traceability system enables the identification and control of issues. From raw material warehousing to finished product delivery, key parameters (such as raw material batch, production time, and test results) are recorded at each stage and linked to a unique traceability code. Regular simulated transportation tests (vibration and drop tests) and weather resistance tests (high-low temperature cycles and humidity tests) are conducted to verify the stability of packaging in extreme environments. For export products, additional compliance tests with destination standards (such as the EU REACH Regulation and US CPSC Standards) are carried out to ensure compliance with local market access requirements.

Location:

Location: