Innovative Design and Trend Insights of Cosmetic Packaging

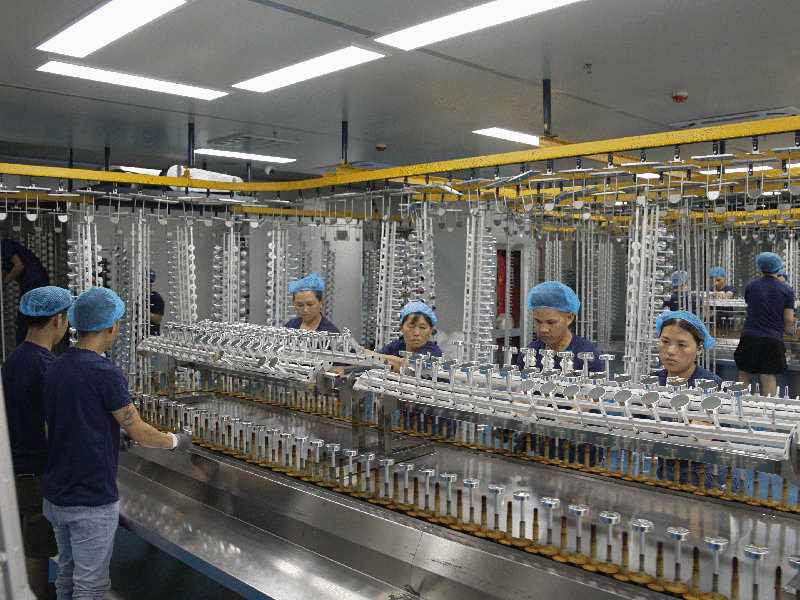

Driven by both the "aesthetic economy" and consumption upgrading, cosmetic packaging has evolved from a mere container into a core carrier for conveying brand value and enhancing user experience. Professional cosmetic packaging enterprises, through forward-looking design and R&D, deeply integrate aesthetic expression, functional innovation, and sustainable concepts to help brands build differentiated competitive advantages.

The diversified expression of design aesthetics has become the core of packaging innovation. For high-end skincare brands, minimalist design language is adopted: the combination of frosted glass and metallic texture creates a light luxury atmosphere, while micro-relief craftsmanship on the details of bottle caps enhances the tactile experience. For color cosmetic packaging, greater emphasis is placed on visual impact—techniques such as gradient electroplating and 3D embossing are used to make lipstick tubes and powder compacts exhibit iridescent effects under light refraction, catering to young consumers’ needs for photo sharing. In addition, customized pattern designs (such as brand-exclusive patterns and co-branded illustrations with artists) are realized through technologies like UV embossing and heat transfer, turning packaging into a "mobile carrier" of brand culture.

Functional innovation focuses on optimizing details of usage scenarios. In skincare packaging, vacuum bottle designs extend the shelf life of serums and creams by 3-6 months by isolating air contact; press-type pump heads adopt a precision valve core structure, controlling the error of each liquid discharge to ±0.1ml, which not only avoids waste but also ensures accurate dosage. In the color cosmetic field, innovative structures such as rotatable eyeshadow palettes and magnetic lipstick caps improve usability; powder compacts equipped with LED fill lights solve the problem of insufficient light for touch-ups outdoors. For travel scenarios, modular sub-bottle sets are launched—bottles can be combined via a snap-on design to save storage space.

Sustainable design has become an inevitable trend in the industry. PCR (Post-Consumer Recycled) plastics (such as recycled PET and PP) are used to make bottle bodies, with recycled content ranging from 30% to 100%, and special processing ensures transparency and strength. Biobased materials (e.g., bamboo fiber, sugarcane bagasse) are applied to packaging boxes, which are biodegradable while retaining unique textures. Detachable structural designs allow packaging components (bottle caps, bottle bodies, pump heads) to be recycled separately, improving material utilization. These designs not only respond to environmental policies but also align with the sustainable consumption concepts of the new generation of consumers.

Location:

Location: